These resources cover a range of topics, from system optimization to maintenance practices and measurement techniques. They can provide valuable guidance for improving the efficiency and performance of compressed air systems in various industrial settings. 1. “Improving Compressed Air System Performance: A Sourcebook for Industry” by the U.S. Department of Energy (DOE): This valuable sourcebook […]

Why is compressor lubricant important?

The lubricated screw air compressors are the most common type in the industrial environment, helping power critical operations in various sectors. Maintaining the quality of your compressor lubricant is very important if you want trouble-free operation. Let’s examine the significance of maintaining high lubricant quality for a lubricated screw air compressor — and its overall […]

How do you check your compressed air storage size?

A very important element of any compressed air system is the system storage volume. But how much do you need? Is your storage capacity big enough? Sufficient system storage is important to the efficiency of a compressed air system because it allows for easier compressor control. Having a large volume connected to your compressors slows […]

When is it time to retire an air compressor?

When is it time to retire a compressor? Your old unit may have served you very well over the last few decades, reliably providing a seemingly endless supply of compressed air. Some units, like the unit in Fig. 1, have been around so long that they have almost become part the family. This design is […]

Compressed air fail: OSHA blow gun regulations

Despite being in force since the early 1990s, compressed air auditors frequently run across compressed air safety hazards when studying their client’s sites. Fig. 1 is a common example where blow guns installed for cleaning have been modified by machine shop personnel. This gun, if the tip is blocked, will deliver over 100 psi to […]

How do you size your air receiver?

Compressed air receivers have become more important in modern compressed air systems. Having an adequately sized main receiver in the compressor room is quite important for the health and efficiency of your air compressors, especially if you have switched from small reciprocating compressors to lubricated screw type. Years ago, the rule of thumb for use […]

Tsunami CORE desiccant dryer available for pre-order with August launch

Tsunami CORE series desiccant dryer is the newest addition to the Air Dryers product line, designed to better serve the automotive and professional coatings industry. This manual change desiccant air dryer features a spring-loaded cartridge style desiccant canister that eliminates dusting and tunneling of the media. It is rated for 25 cfm and is designed […]

Compressed air success! Found gold

A wood products company decided to conduct a treasure hunt for energy savings on its compressed air system. Plant personnel were scheduled to have a production outage during a one-week period — and so they invited a compressed air expert to help them identify any suggested improvements to the system. Industrial plants frequently have staff […]

Elgi announces energy-saving dryers at the 2023 AICD conference

Elgi North America will introduce the AR Premium Series Energy Saving Cycling Refrigerated Air Dryers at the annual Association of Independent Compressor Distributors (AICD) conference in Grapevine, Texas, taking place from May 21–23. In addition, Elgi will showcase its expanded range of AB Series oil-free screw air compressors in 15-30 hp, offering a more affordable […]

Compressed air fail: Poor disposal

A lumber processor installed a remote lubricant-injected rotary screw compressor in an outbuilding to supply compressed air to a debarking system out in the yard. Lubricant injected air compressors normally pass some compressor oil into the system — usually about 4 parts per million for a well-maintained compressor — even though there is an air/oil […]

New dry rotary vane vacuum pumps from Atlas Copco

Atlas Copco has developed its new DVS vacuum pump series with a focus on this requirement profile. The result: the DVS models are oil-free, dry rotary vane pumps that guarantee emission-free, quiet operation and do not contaminate the processes. High efficiency at competitive costs “This makes them ideally suited for a wide range of applications, […]

Kaeser’s new active oil-water separator shown at Hannover Fair

With the intelligent Aquamat i.CF, Kaeser Kompressoren has redefined condensate treatment. Available for delivery volumes up to 90 m³/min, this new oil-water separator now comes equipped for the first time with the Aquamat Control internal controller, which undertakes active management of the process while simplifying maintenance planning and making service work cleaner. Wherever compressed air […]

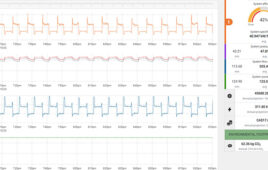

Compressed air fail: Strange CFM profile

A sawmill maintenance department requested a compressed air assessment to determine the efficiency of its system and to find out if any improvements could be made to reduce their compressed air system operating costs. They called in an auditor who placed data logging equipment to measure pressure, flow, and power. From these measurements, the auditor […]

Rotary screw compressors more efficient than ever

Rotary screw compressors are the dependable backbone of an industrial compressed air supply. With a multitude of features, the innovative CSD/CSDX range from Kaeser Kompressoren fulfills this role more efficiently, dependably, and economically than ever before, while at the same time reducing a company’s CO² footprint. The most important highlight of these compressors is their […]

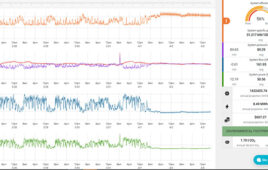

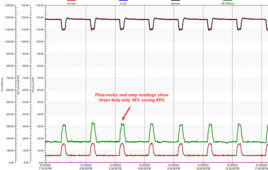

Compressed air fail: Air dryer robbery

A routine audit of a wood products company has turned up some surprising results on a system that was thought to be very efficient. The system is simple — one compressor, a 100-hp variable speed drive controlled (VSD) screw compressor, and a heatless desiccant air dryer. Data loggers were placed on the system by a […]

Compressed air fail: Check valves

A metal products company had a system of multiple compressors arranged in two compressor rooms. The maintenance workers were having constant problems setting up their compressors to run in a logical sequence. For some reason, the main compressor would never turn off in automatic start, which would allow them to save energy. The big compressor […]

Compressed air fail: Remote coolers

A wood products company had issues with its compressor room. Despite installing good filtering, the compressor oil and air coolers would clog up with sawdust — and the compressors would constantly overheat. The maintenance manager, remembering something from one of his previous jobs, decided to move his compressor coolers outdoors. This worked great in the […]

Quality air is critical for aerospace manufacturing

Compressed air quality is crucial for aerospace manufacturing, as aircraft components and tools must be of the highest quality and precision. This demanding standard for component quality urges aerospace manufacturers to utilize compressed air with specific requirements. The air must be clean, dry, and unvaried under pressure. If the air becomes dirty, moist, or varies […]

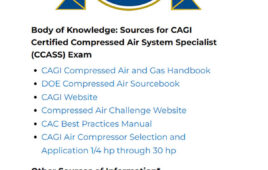

Reduced price for CAGI exams offered

Are you a compressed air professional who would like to get CAGI Certified? Currently there is a reduced price for writing the Certified Compressed Air System Specialist exam to obtain your CCASS designation. Having this designation is important as it shows you have the knowledge required to be competent in the industry, knowing the general […]

Packaging manufacturer increases uptime with oil-free compressed air technology

Oil-free compressed air is crucial for packaging companies as there is zero tolerance for oil vapor presence in production. For a flexible packaging company serving North America’s food, beverage, and pharmaceutical industries, detecting oil contamination would mean a facility shutting down, resulting in significant production loss and maintenance costs. In addition, if oil traces reach […]

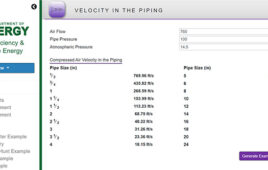

Why is compressed air pipeline velocity important?

How do you determine the diameter of the compressor room header pipe? Many piping installers might take a look at the outlet diameter of the air compressor and chose a similar size, but due to the variety of different outlet sizes, and the combination of flow of multiple compressors in a room this may not […]

EPEQ AIR20 provides dependable air from proven compressor

When you need clean quiet power with no fumes or extensive heat build-up, the EPEQ AIR20 is a proven compressor choice. EPEQ Air Compressors are designed to be ultra-efficient when paired with the ELiMENT Battery. The EPEQ AIR20 reciprocating compressor provides 20 cfm at 150 psi, which is suitable for intermittent air use while performing […]

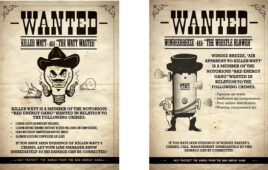

Wanted for criminal waste: Killer Watt!

Did you know that there are criminals hiding in your plant wasting your energy and hard-earned dollars? In fact, they are nasty, terrible creatures who deserve to be tried and convicted. Be sure to hunt them down and arrest their wasteful ways. Remember that all it takes is a little effort — and it could […]

Compressed air: Dewpoint control saves

A medicinal products supply company installed a 600-cfm heatless desiccant dryer to condition their air, due to the nature of their business they wanted high air quality. They also wanted to save energy, so they upgraded this dryer to dew point dependent switching, a control mode that turns off the 90-cfm purge flow when output […]

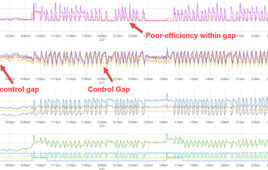

How do I fix a VSD compressor control gap?

Question: I have a 1,000 cfm VSD compressor, but due to motor and control problems it is producing only 560 cfm. I notice my compressors are fighting with each other. What new size of VSD do I need to fix this problem? Answer: The basic rule in running with a VSD is that the variable […]