An industrial compressed air user was having a difficult time with their high pressure compressed air system. The compressed air demand required instrument quality air, so a heatless desiccant air dryer was installed. The dryer uses activated alumina within its chambers to strip off the moisture from the compressed air flow using an adsorption process […]

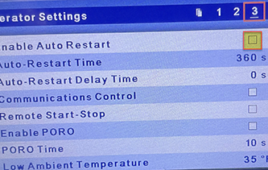

Compressed air fail: Auto mode was forgotten

One little button click can save thousands of dollars in wasted electrical and maintenance costs on air compressors. Recently, a compressed air auditor encountered the same problem in two different plants; operators had failed to select “Auto Mode” on their compressors. Both units were 150-hp lubricated screw compressor installed in a system of multiple compressors. […]

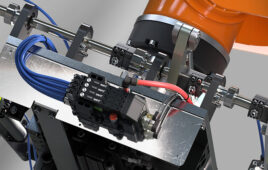

Precise and localized pneumatics complement advanced motion controls in packaging machines

Packaging machine manufacturer Coesia and its sister companies rely on system integration for efficient, precise and fast operations. With a focus on streamlined systems that reduce pouch or carton handoffs and offer the ability to move non-standard sized materials, Coesia companies R.A. Jones and MGS turn to modern motion control systems married with precision pneumatics […]

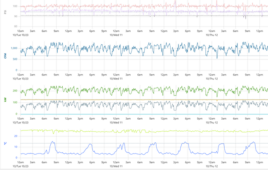

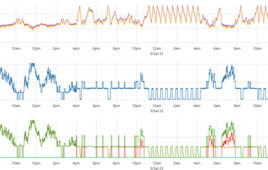

Compressed air fail: Dew point bump

A compressed air auditor was hired to have a close look at the main compressed air system at a farm implement manufacturing plant. Data collection instruments were placed on the system to measure pressure, flow, and power. The auditor also placed a dewpoint meter at the discharge of the compressor room, after the main air […]

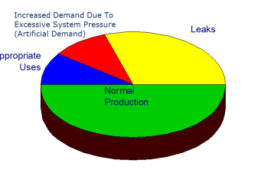

Compressed air fail: Here’s a record you don’t want to break

One important item discussed in Compressed Air Challenge’s Fundamentals of Compressed Air Systems seminars is leakage. The most common waste category is compressed air. When studies are done looking at leakage rates compared to the total amount of compressed air produced, on average somewhere between 20% and 30% is found at manufacturing facilities (Fig. 1). […]

How can you reduce air leaks without turning a wrench?

What if you could reduce all your leaks without turning a wrench? Well, it is possible with good pressure control. And sometimes it is as easy as turning a knob. The principle is shown in the following orifice chart, Fig. 1. As the pressure to a leak reduces by 1 psi, the flow consumed by […]

Helix connected platform provides real-time insights for compressed air systems

Ingersoll Rand announces the launch of its Helix Connected Platform, which provides valuable insights on compressed air systems to ensure reliability and extend equipment life. Developed for industrial applications to maximize uptime and peace of mind, the Helix Connected Platform provides continuous, real-time data monitoring for compressed air systems to enable maximum operational uptime. Advanced […]

Compressed air fail: Dead PFCs

One of many energy conservation measures available to industrial users is the use of pressure/flow control regulators. These are installed in systems to reduce the plant pressure while leaving the air compressors to operate within a wide pressure band, making them more efficient. A compressed air pressure/flow controller is a device used to regulate and […]

Kaishan USA launches industrial, oil-free rotary screw compressor

Kaishan USA has introduced a new series of industrial, oil-free rotary screw air compressors, the KROF. Plant managers and operators seeking to stay ahead of the ever-changing innovation that supports the food and beverage industry will find unrivaled value in the technical depth of the KROF. The KROF is a two-stage oil-free rotary screw air […]

Compressed air fail: Pony compressor

A large automotive service shop had two 100-hp compressors, one being a VSD, both available to supply the compressed air they needed for painting and body assembly of large vehicles. The load was full of peaks, and the maintenance staff needed up to 400 cfm to provide flow to paint booths and breathing air hoods […]

Compressed air fail: Penny pinching

A farm implement manufacturer expanded its facility about 15 years ago, and personnel decided they wanted a premium compressed air system. They purchased three very efficient two-stage premium compressors, one being a VSD, and connected the equipment with large piping to reduce pressure loss. Filters were mist-eliminator style to reduce pressure loss. Air dryers were […]

Are pneumatic technologies at risk of becoming obsolete?

Last month, I had the pleasure of attending Pack Expo in Las Vegas for the first time in about five years. I’ve always enjoyed that show, seeing all the packaging machinery and conveyors operating, watching the pneumatics and motion control technologies do what they do best. But I did notice one thing this year — a […]

Compressed air fail: Poor sealing methods

If you have ever done leakage detection with an ultrasonic leak detector you will get to know the common leak locations. If you have no detector, there is no excuse these days, excellent equipment is available for you to purchase at a reasonable price, go get it! A common sight — or rather sound — […]

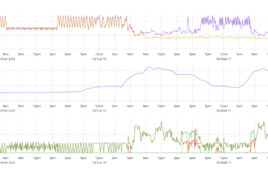

Finding energy efficiency in the cloud

Every manufacturer using compressed air shares the challenge of keeping compressed air systems running efficiently and reliably. Depending on the industry, the compressed air system accounts for 10-50% of a plant’s energy usage and is as essential to uptime as electricity. But compressors are inherently inefficient. Leakage, irregular maintenance, pressure settings, and controls contribute to […]

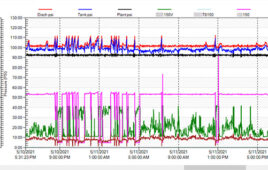

Compressed air fail: Bearing cooling

A wood products company hired a compressed air auditor to check out its system and try to discover why it now needed to run three compressors rather than the normal two units that previously satisfied the plant demand. The auditor placed instruments on their system to measure pressure, power, temperature, and flow — and quickly […]

Compressed air fail: Breathing air purifier

A metal process plant has two breathing air purifiers installed on site for the protection of its personnel. These units are installed to ensure hazardous Carbon Monoxide is kept out of breathing air. Recently, the two systems were evaluated by a compressed air auditor. When paint fumes or metal particles are in the ambient air […]

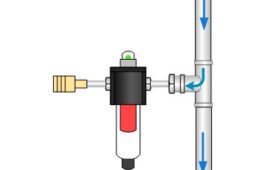

Should wet compressed air receiver tanks be outdoors?

During plant inspections, it is often noticed that compressed air receiver tanks are installed outdoors. This is done for a reason — and is a good idea, in many cases, because it benefits the operation of air drying and filtering equipment and produces better quality compressed air when hot summer days cause worst-case conditions. Here […]

Compressed air fail: Remote cooler install

A wood products company called in a compressed air auditor to have a look at its compressed air system. System reliability was poor, and the staff was having issues with the main compressor, a 200-hp air cooled screw compressor that carried most of the plant load. This compressor was rated at 100 psi, but recently […]

Compressed air fail: Vacuum pick-up

A metal products manufacturer had a production problem in one of its processing areas. The maintenance staff had increased the discharge pressure on their air compressors to help with the issue, but it seemed the problem would come back occasionally with no warning. Fig. 1 shows the problematic item, a vacuum pick-up crane. When the […]

How can you spot wasted compressed air?

In a noisy industrial expensive plant, air leaks are everywhere, but hard to detect because the ambient roar washes out the sound of air leaving your system. But strange as it may seem, sometimes you can see compressed air leaks, or more accurately, you can see the result of the air escaping! Fig. 1 […]

Compact, efficient and intelligent multi-stage ejector

piCompact 10X Smart is a compact, efficient, and intelligent ejector that enables you to take the next step in production control and ease of use. Based on COAX technology and integrated IO-Link technology, piCompact 10X Smart offers enhanced flexibility, quicker installation, and improved customization to fit your needs. Building on the air-driven, multistage ejector piCompact […]

Compressed air fail: Nozzles check

By Ron Marshall A metal parts company had dozens of media blasters installed in its production areas to clean its products for final processing. These blast cabinets were in constant use throughout their 16-hour production day and consumed a significant part of the peak compressed air demands. The staff found that they were running out […]

Rockwell Automation and CaseiZ help manufacturers reduce energy costs

Nearly every manufacturing facility uses compressed air. And all share the challenge of keeping compressed air systems running efficiently and reliably. Depending on the industry (e.g., automotive, consumer goods, mining, etc.), the compressed air system accounts for 10-50% of a plant’s energy usage and is as essential to uptime as electricity. But compressors are inherently […]

Why does my compressed air quality go down in summer?

Are you spending your summer struggling with the quality of your compressed air, with stinky, rusty water pouring out of your pipes? When it comes to air quality, the hot summer months are the most challenging time for most compressed air systems, and to avoid problems, you need to plan for the worst-case scenario. Typically, […]

Compressed air fail: You forgot one thing

A meat processing company air upgraded its compressed air system to increase capacity and reduce energy consumption. They installed large, premium efficiency VSD compressors, a smart compressor controller, efficient filters, large storage, and heated blower desiccant dryers connected with oversized compressor room piping — all in an effort to reduce pressure loss. The maintenance workers […]